Approvals and Certifications

Precision Bending Technology (PBT) know that manufacturing quality parts is achieved with an ongoing process that requires consistency, and efficiency. We are constantly striving for the highest standard of quality will meet our customers’ requirements.

Attention to detail and quality is the key to our manufacturing processes. Precision Bending Technology meets the quality standards of ISO9001:2015.

In-House Quality Process Management

We have created a design and review process that including the following manufacturing activities:

- Blanking: determine the most efficient way to create tubing blanks for bending your parts

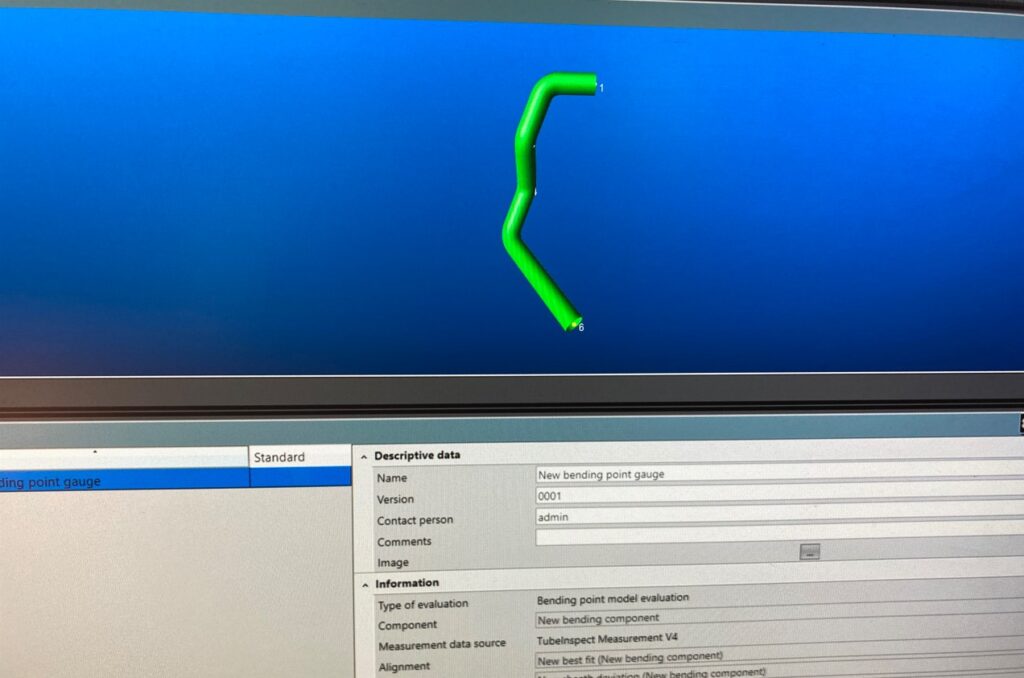

- Bending: evaluate the material used including material ductility, fixturing and other blank length considerations

- Saws: strive to use trim sheer process to reduce costs

- End Finishing: create tooling list and develop checking gauges

- Drilling: consider plasma drilling compared to kidder punch

- Welding: if needed, we determine fixture and jigs and any part of the process that can be automated

- Pressure Test: ensure the parts can withstand the required pressure

- External Preparation: prepare parts that need insulation or painting for final delivery.

During this process we will evaluate when design changes can help to reduce costs, or if a higher volume of production can reduce the individual part prices.

Are Your Ready to Start a Project?

Contact our team to find out more about our capabilities.

Contact Us

General Contact Form